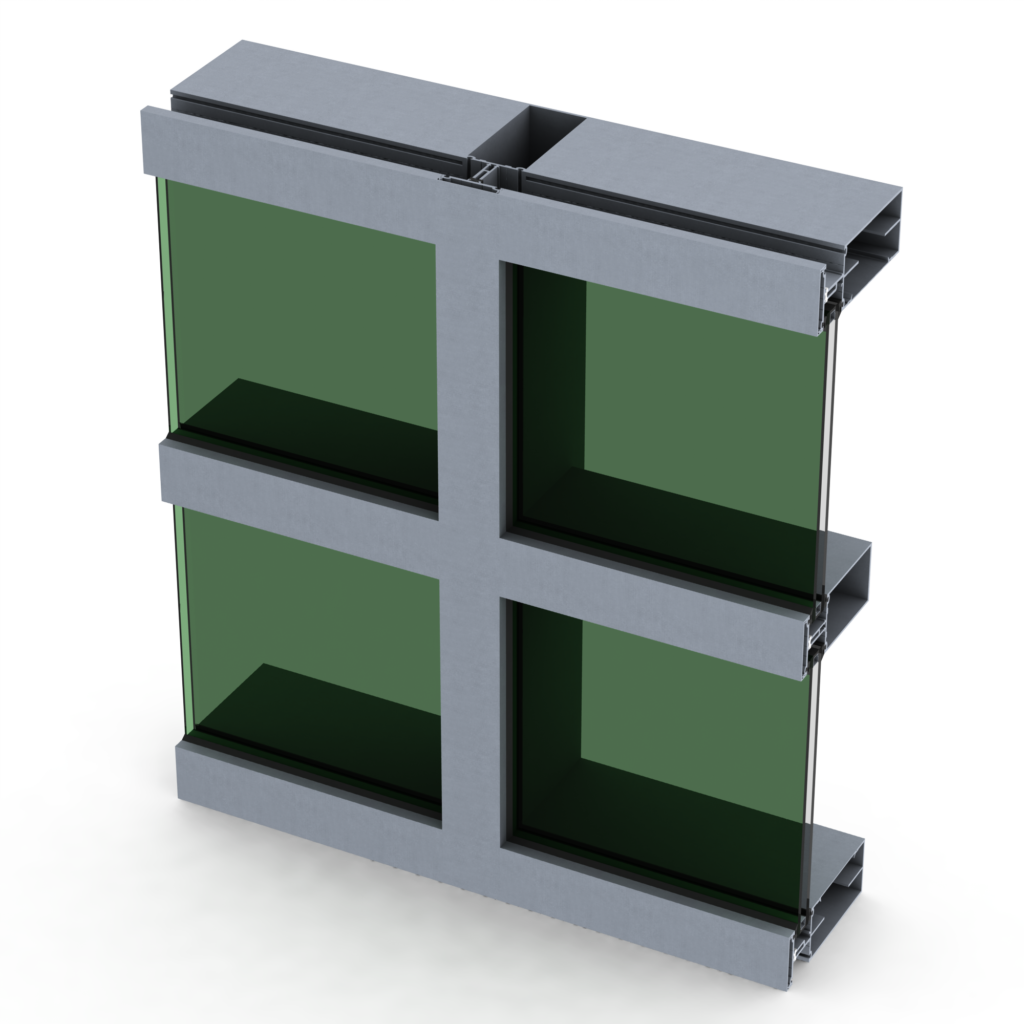

PLCW-700 SERIES 2 1/2” x 7”

Product: PLCW-700 as manufactured by PRL Glass Systems, Inc.

- Manufacturer Qualifications: Minimum 5 year experience manufacturing similar products.

- Installer Qualifications: Minimum 2 year experience installing similar products.

- Mock-Up: Provide a mock-up for evaluation of surface preparation techniques and application workmanship.

- Finish areas designated by Architect.

- Do not proceed with remaining work until workmanship is approved by Architect.

- Refinish mock-up area as required to produce acceptable work.

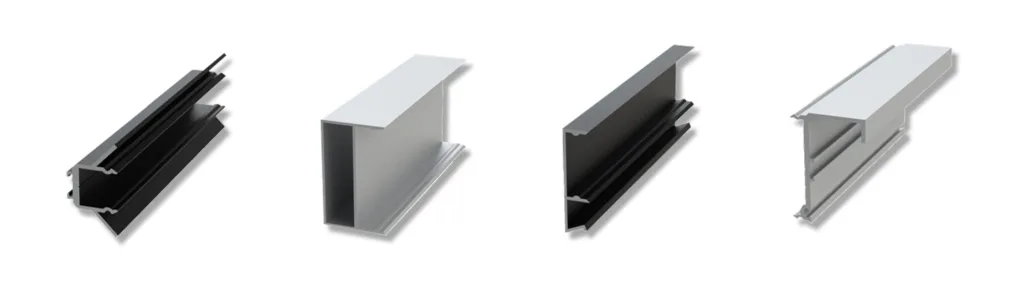

- Material: Frames, assembly clips, trims and miscellaneous extrusions shall be extruded from Aluminum 6063-T6 alloy.

- Glazing Gaskets:

- Class II color anodized aluminum shall:

- Color: Champagne.

- Color: Light

- Color: Medium

- Color: Dark

- Color: Black

- Structural silicone compatible gasket: true silicone gasket -70 Durometer Shore "A", complying with ASTM C1115, Type C.

- Thermal isolators: extruded rigid Geon complying with AAMA-303 and ASTM-D-1784-9.

- End Dams: Pre-molded end dams made from closed cell EPDM (Ethylene Propylene Diene Monomer) sponge to ASTM C509.

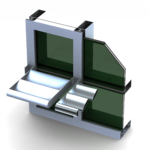

Learn more information about our contfiguration Max Cabo Bipass System

by clicking here.

1.1 REFERENCES

A. American Architectural Manufacturers Association (AAMA):

- 1. AAMA/NWWDA 101/I.S. 2-97 – Voluntary Specification, Performance Requirements and Test Procedures for Air Leakage Resistance, Water Penetration Resistance, Structural Loading, Forced Entry Resistance.

- 2. AAMA-501.1 – Standard Test Method for Water Penetration of Windows, Curtain Walls and Doors Using Dynamic Pressure.

- 3. AAMA 501.4 – Recommended Static Test Method for Evaluating Curtain Wall and Storefront Systems Subjected to Seismic and Wind Induced Interstory Drifts.

- 4. AAMA 2605 – Voluntary Specification, Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels.

B. ASTM International (ASTM):

- 1. ASTM B 221 – Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- 2. ASTM E 283 – Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors under Specified Pressure Differences across the Specimen.

- 3. ASTM E330 – Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference.

- 4. ASTM E 331 – Test Method for Water Penetration of Exterior Windows, Curtain Walls, and Doors by Uniform Static Air Pressure Difference.

These installation instructions are generic in nature but specific to the PRL curtain wall systems. They are specific to all of PRL’s curtainwalls including the PLCW-600, PLCW-700 and PLCW-1000. Because each project will have differing conditions, each project should have job specific drawings prepared by journeymen drafters or engineers who are familiar with curtain-wall construction and have an intimate understanding of PRL’s curtain wall system and how to integrate it into the construction details specific to the project it is being used on. The shop drawings will take precedence over these instructions as they are project specific. You may refer to PRL’s test reports for further familiarity with construction details of the curtain walls. When in doubt contact your PRL technical representative.

PROJECT NAME = cw701 PROJECT NUMBER=1

Ixx – NEUTRAL MOMENT OF INERTIA = 7.77083 AREA = 1.84775

Iyy – NEUTRAL MOMENT OF INERTIA = 1.71654 PERIMETER = 19.7867

Ixy – NEUTRAL MOMENT OF INERTIA = .000000

Ip – POLAR MOMENT OF INERTIA = 9.48737

Imax – MAXIMUM MOMENT OF INERTIA = 7.77083

Imin – MINIMUM MOMENT OF INERTIA = 1.71654

Theta – PRINCIPLE TO LOCAL ANGLE = .000000

Rmax – MAXIMUM RADIUS OF GYRATION= 2.05074

Rmin – MINIMUM RADIUS OF GYRATION= .963840

————————————

IXX – GLOBAL MOMENT OF INERTIA = 27.8144

IYY – GLOBAL MOMENT OF INERTIA = 4.60365

IXY – GLOBAL MOMENT OF INERTIA = 7.60710

IP – GLOBAL POLAR MOM. OF INER.= 32.4180

XCG – X- CENTER OF GRAVITY = 1.25000

YCG – Y- CENTER OF GRAVITY = 3.29356

AXX – GLOBAL AREA MOMENT ABOUT-X= 6.08568

AYY – GLOBAL AREA MOMENT ABOUT-Y= 2.30969

MATERIALS AND FINISHES

Glass Thickness Color:

- Color: Clear

- Color: Starphire

- Color: Texture

- Color: Grey

- Color: Bronze

- Color: Laminated

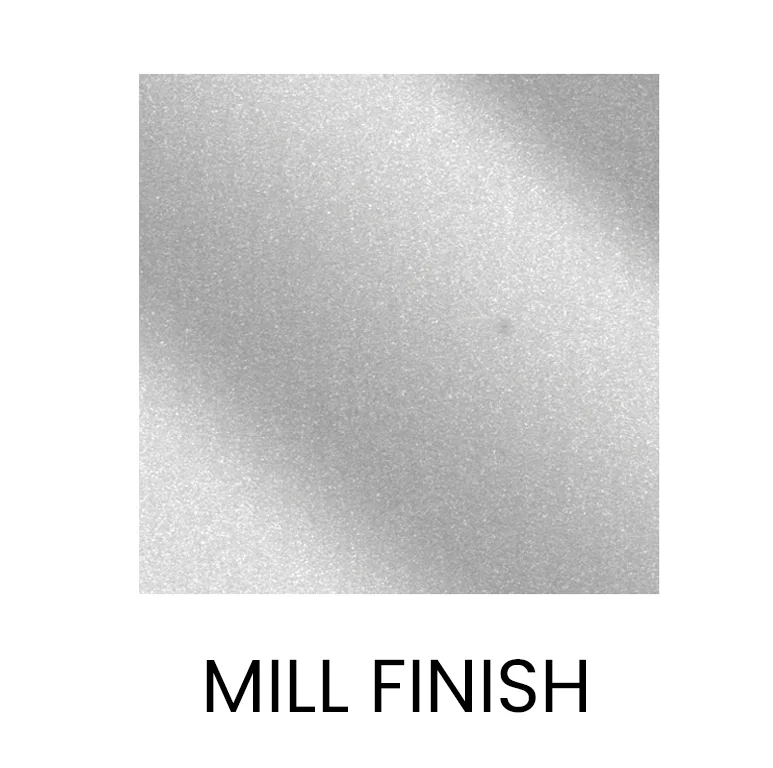

Avilable finishes aluminum shall conform:

- Color: Clear Anodize

- Color: Bronze Anodize

- Color: Mill Finish

- Air infiltration: Limit air leakage through fixed glazing and frames to 026 cfm/ft2/min (0.01 L/s/m2) when tested in accordance with ASTM E-283-04 at a cross pressure of 6.24 psf (0.30 kPa).

- Water Penetration under Static Pressure: System shall not evidence uncontrolled water penetration at a cross pressure of 15 psf (103 kPa) when tested in accordance with ASTM-E331-00.

- Water Penetration under Dynamic Pressure: System shall not evidence uncontrolled water penetration at a cross pressure of 15 psf (103 kPa) when tested in accordance with AAMA-501.1-05.

EXPLORE ALL THE PRODUCTS

Love The Results

Discover our entire product gallery by clicking here